Join us at Pack Expo, Las Vegas, booth #4836 on September 11-13

Register here for complimentary passes or use code 96M17.

Bradman Lake will be showcasing the latest SL903 high speed end load cartoner, featuring a low-height carton hopper. The SL903 is made of durable stainless steel and can erect, load and close cartons within one frame. The machine has a wide range of optional features that enable it to be customized to meet the specific needs of customers.

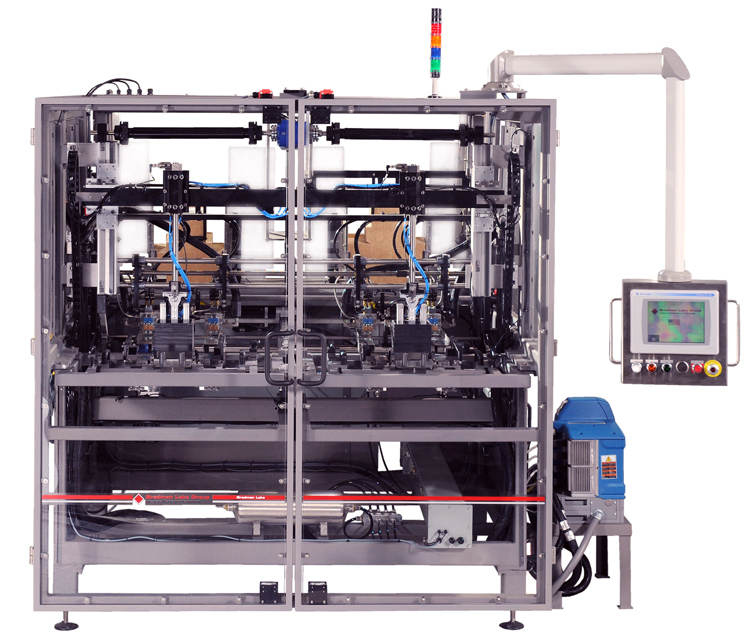

Bradman Lake will also be displaying a top load packaging solution that includes the servo driven HSS Double Head carton and tray former. The HSS is an innovative machine that will simultaneously erect cartons using both hot melt glue and four corner locks, showcasing its versatility for various packaging requirements. After forming, the cartons will be transferred to the IL120 carton closer. The IL120 utilizes Bradman Lake’s unique ‘Flexible Carton Control’ (FCC) technology allowing cartons containing products of inconsistent size to be closed without jamming. The machine also features quick and easy tool-less size changeovers, significantly reducing downtime and increasing productivity for customers running several different carton sizes.

HSS Carton and Tray Erector / Former

IL120 Carton Closer

Additionally, Bradman Lake will be exhibiting the HS Mini carton and tray former. This machine is ideal for small to medium-sized businesses that require a high-quality carton former in a small footprint. Although compact, the HS Mini retains the same advanced features found in the standard size former.

The company’s display at Pack Expo Las Vegas will showcase its unique capabilities offering both top load and side load cartoning approaches. Visitors will have the opportunity to see the features and benefits of each approach and choose the best solution for their needs.

Visitors to the booth will also have an opportunity to see a curated video collection. These videos will illustrate how the packaging equipment on display seamlessly integrates with Bradman Lake’s upstream equipment, that includes product distribution and flow wrappers and downstream equipment that includes case packers, shrink wrappers and palletizers, creating a flawless end-to-end process. This reaffirms Bradman Lake as the ultimate one-stop shop for packaging solutions – where innovation meets integration.

“We are excited to exhibit our latest packaging equipment at Pack Expo Las Vegas,” said Patrick Dwyer, President at Bradman Lake Inc. “We believe that our products offer the best in terms of quality, performance, and flexibility, and we are confident that visitors to our booth will be impressed.”

Features and benefits for all Bradman Lake’s equipment:

Bradman Lake packaging equipment sets the benchmark for primary, secondary and tertiary packaging. Equipment can be supplied as a ‘stand-alone’ machine for low speed, hand-fed applications, or as a fully automatic system to meet the demands of the most sophisticated hi-tech processing and packaging lines. They have become the machines of choice for many multinational manufacturers operating in the bakery & biscuit, chocolate & confectionery, dry foods, chilled & frozen foods, pharmaceutical, and healthcare industries.

Experience. Bradman Lake has a large installed base; our customers benefit from over 75 years of knowledge in designing and building packaging equipment. Bradman Lake is an established brand with a high reputation for machine reliability and value for money worldwide. Its position as an innovative, progressive and forward-thinking global supplier of packaging solutions derives from vast industry experience, a consultative customer driven approach, delivering commercially viable solutions with strong project management and a commendable health and safety record.

All Bradman Lake products are the result of thoroughgoing research and development and are developed from an undertaking that every project, no matter how small or technically challenging, will be a custom solution to meet exact customer requirements. This responsive, solutions-based approach has helped establish Bradman Lake as a leading global provider of future-proof packaging technology.

Flexibility, “Future Proof” Principal. The ergonomic modular design provides the ultimate flexibility to handle a wide range of products, carton formats and sizes that can be rapidly adapted to specific requirements enabling our customers to easily meet the demands of the fast-changing markets at any time in the future.

Sustainability. Environmental sustainability is an important focus for Bradman Lake, both in machine development and business operation. As well as promoting recycled packaging, it seeks to minimize packaging material waste through various equipment features. Ergonomic equipment design enables concurrent task completion in one compact frame, reducing spatial requirements, lowering energy and air consumption while ensuring no harmful emissions are produced.

Bradman Lake is proud to communicate its machinery helps to remove many millions of single use plastic trays year on year!

Safety and Hygiene. Robust and well-built to the latest safety and hygiene standards. Upgradable machine construction to handle wash-down applications that are required in the food and healthcare industries. Machine guarding has been designed to provide operator safety, maximum visibility of operation and excellent machine access.

From Process to Pallet. Bradman Lake provides true, single-source turnkey systems, with project management from initial concept to site acceptance and beyond. The benefits to customers include commonality of engineering standards and parts; a single servo motor size, common wiring patterns and identical HMI look-and-feel all contribute to ease of use and operation; a single point of contact for procurement; project manager and aftermarket; FAT for full system occurs in single location and systems are fully integrated and tested prior to delivery resulting in expedited start up.

Intuitive HMIs and a common control platform offer customers an easier method of extracting information from a single source, as well as seamless exchange of data upstream and downstream. A single network infrastructure offers unprecedented levels of visibility, flexibility and scalability to respond to market opportunities and operational threats.

Initial Capital Savings. The core competence of the equipment is its unique capability for seamless future integration with other Bradman Lake innovative equipment to achieve full automation and yet retain initial capital savings.

Smart Layout. Compact footprint which is available in several orientations to suit plant layout and incorporates narrow integral electrical cabinets with easy access. All machines are designed with minimum frame sizes and easy-access guard design.

Customer Service: Backed by readily available and award-winning customer support, commercial commitment, resources, and spare parts delivery.

About Bradman Lake

Established in 1948, Bradman Lake provides innovative packaging solutions to an international client base. The company is a leading designer and manufacturer of packing machinery and turnkey systems to the bakery & biscuit, chocolate & confectionery, dry foods, chilled and frozen foods, consumer, pharmaceutical and healthcare sectors. In 2022 the company was awarded the prestigious Queens Award for Enterprise. Bradman Lake’s manufacturing plants are located at Beccles and Bristol in the UK and Rock Hill, SC, in the United States. Bradman Lake is a wholly owned subsidiary of the multi-disciplined UK engineering and manufacturing group, Langley Holdings plc.