Slicers

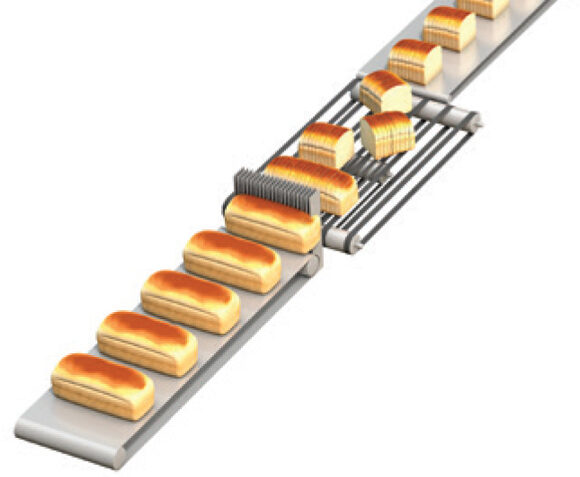

The slicing machines can be stand-alone units or can form a part of a larger automatic system. Slicers are available with longer cutting strokes for optimal efficiency and also a blade oiling system for lubrication on heavy rye products. There are also options for additional control belts to give better control of free-baked products, which can vary significantly in size.

We offer a comprehensive range of slicers to suit a wide variety of products. Machines are tailor-made to suit customer’s exact requirements.

B51/LB65/LB90 Reciprocating Slicers

The operation of the reciprocating blade Slicer is both simple and efficient, with the products being delivered to the slicing position by side and bottom feed belts.

The slicing process is performed by knives mounted in two frames (half the total number of knives in each frame), which are reciprocated in opposite directions while the product is pushed through. The reciprocating motion is effected by connecting rods mounted to a double throw dynamically balanced crankshaft totally enclosed in an oil-filled crankcase.

The speed of product feed is by an Inverter controlled motor mounted on the side of the slicer. When linked to an Ibonhart Bagger, this motor is controlled from within the bagger to ensure optimum line efficiency.

- Easy slice thickness change by changing the cutting frames.

- Ability to bag whole loaf by simply removing the frames.

- Minimal crumb loss.

- Bread Slicer is electronically linked to the bagger control system resulting in the feed rates being identical.

BS420/BS420R/BS420A Band Slicers

The operation of the high capacity Band Slicer is for all types of bread.

The band blades are tightened between two hard chrome-coated steel drums. With the hard alloy blade guides and long-lasting blades, the slices are cut straight, and the thickness of the slice always remains exact.

The BS420 Band Slicer is equipped with an adjustable infeed system with driven bottom, side, and top belts. Such a well-controlled feeding is ideal for a wide variety of products, especially when free-baked products are concerned. The loading of the machine takes place directly from the cooling conveyors or can be manually loaded.

The BS420R is available for rye type bread and is equipped with a larger drive motor and an integrated oiling system.

The BS420A is our flag-ship slicer with a fully automatic adjustable slice thickness linked to the bagger touch screen for ease of slice thickness adjustment.

The optimum starting thickness will be selected based on the customer’s requirements.

DS4/BS2 Disc Slicers

The DS4 Disk Slicer is designed to hinge cut rolls leaving an adjustable depth uncut portion.

The product is controlled via top and bottom conveyors, which along with the blade height and depth, are adjusted at a single point by hand wheels.

Available in single, twin, and four-lane versions.

The BS2 Band Slicer is designed to fully cut rolls, either single or double cut.

Available in twin lane format.

Both systems can be integrated into our collation systems and feed either bagging or flow wrapping equipment.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request